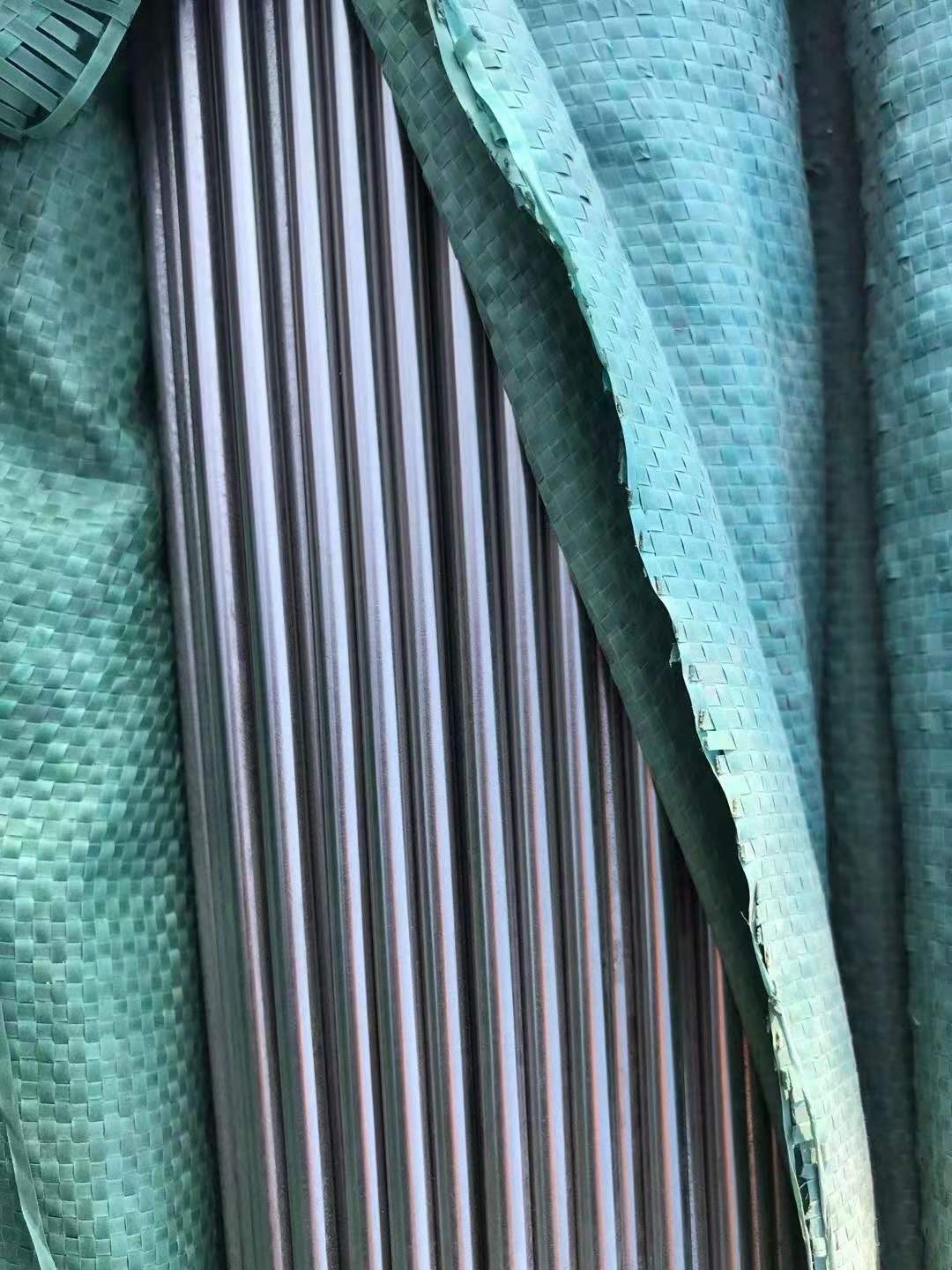

Production procedure:

Raw elements (C, Fe, Ni, Mn, Cr and Cu), smelted into ingots by AOD finery, hot rolled into black surface, pickling into acid liquid, polished by automatically machine and cutting into pieces

Standards:

ASTM A276, A484, A564, A581, A582, EN 10272, JIS4303, JIS G 431, JIS G 4311 and JIS G 4318

Materials:

300series:301,302,303,304,304L,309,309s,310,310S,316,316L,316Ti,317L,321,347,

200series:201,202,202cu,204;

400series:409,409L,410,420,430,431,440;

Others:2205,2507,2906,330,660,630,631,17-4ph,17-7 ph, S31803904L,etc

Duplex stainless steel:

(S31803,S22053,S25073,S22253,S32205,S32304;2205,2507)

Nickle alloy Steel:

(904l,347,347h,317,317l,316ti,254mo)

Dimensions:

Hot-rolled: Ø5.5 to 110mm

Cold-drawn: Ø2 to 50mm

forged: Ø110 to 500mm

Normal length: 1000 to 6000mm

Tolerance: h9&h11

Features:

Nice appearance of cold-rolled product gloss

Nice high temperature strength

Nice work-hardening (after processing weakly magnetic)

Non-magnetic state solution

Suitable for architectural, construction and other applications