430 stainless steel sheet/plate:

Chemical composition of 430 stainless steel coil:

C:≤0.12% Si:≤0.75% Mn:≤1% P:≤0.040% S:≤0.030% Ni:≤0.60% Cr:16 ~ 18%

Surface grade of 430 stainless steel sheet/plate

different state , dirt and corrosion resistance are not the same. NO.1, 1D, 2D, 2B, N0.4, HL, BA, Mirror, and other surface treatment.

1)1D:The surface has a discontinuous granular, also known as the fog surface.

Processing: hot rolling + annealing shot blasting pickling + cold rolling + annealing pickling.

2)2D:slightly shiny silver-white

Processing: hot rolling + annealing shot blasting pickling + cold rolling + annealing pickling.

3)2B:Silver white and better than the 2D surface gloss and smooth flatness.

Processing: hot rolling + annealing shot blasting pickling + cold rolling + annealing pickling + quenching and tempering rolling

4)BA:Excellent surface gloss, has a high reflectivity, as the mirror surface

Processing technology: hot rolling + annealing shot blasting pickling + cold rolling + annealing pickling + surface polishing + quenching and tempering rolling

5)N0.3:Has a good gloss, surface was rough lines

Processing: 2D products or 2B with 100~120 (JIS R6002) abrasive material polishing and temper rolling.

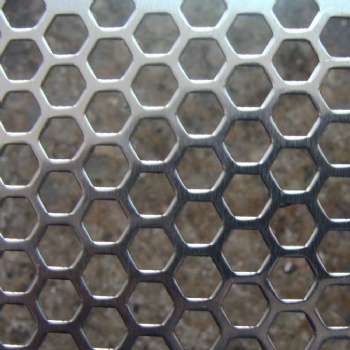

6)No.4:Have better gloss, surface is fine lines.

Processing: 2D products or 2B with 150~180 (JIS R6002) abrasive material polishing and temper rolling.

7)HL:Gray hair and stripes.

Processing technology: the 2D or 2B products with the appropriate size of the abrasive material for polishing the surface of a continuous grinding

8)Mirror:In a state of mirror

Processing technology: the 2D or 2B products with the appropriate size of the abrasive material for grinding and polishing to the mirror effect

Applications

Typical applications for 430 grade include:

Linings for dish washers

Refrigerator cabinet panels

Automotive trim

Lashing Wire

Element Supports

Stove trim rings

Fasteners

Chimney Liners

Typical applications for 430F grade include:

Repetition machined components

Specifications:

UNS: ASTM/ASTE S43000

DIN: 1.4016